Fiber reinforced polymer (FRP) is probably something you have heard of if you are interested in polymers, plastics, or composites. But what is it exactly? And why does it matter? This chapter examines the basics of FRP and how it works. It also discusses some of its uses and qualities, like how it can build cars and aircraft.

How It Is Made

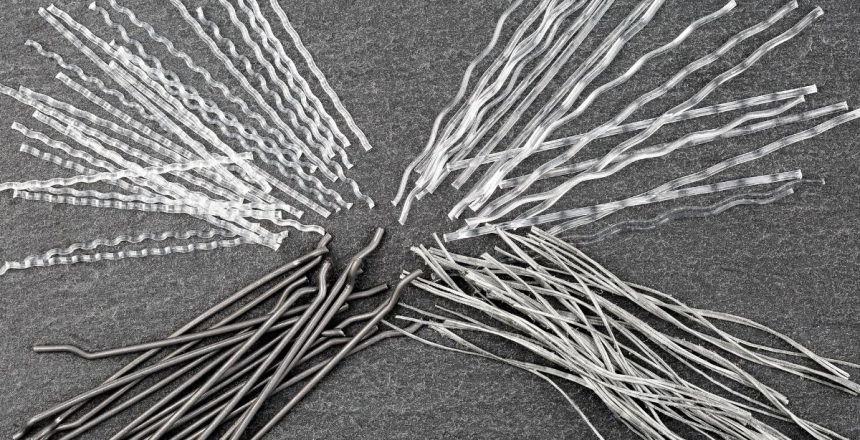

A fiber-reinforced polymer is a composite made by mixing a polymer matrix with a reinforcing fiber. The word “fiber” refers to the thin strands of material woven into FRP products or bonded to their surfaces. The fibers can be made of glass, carbon, or other natural or synthetic material.

FRP products have two types of reinforcement: continuous and discontinuous. Continuous reinforcements are woven into the polymer matrix, while discontinuous reinforcements are added on top of or beneath it (also known as pre-impregnated).

Naturally Occurring Fiber Reinforced Polymers

Wood is a composite material composed of cellulose fibers bound by lignin and hemicellulose in an organic compound matrix. The fiber reinforcements within the tree comprise the same components but in varying proportions depending on the tree’s species (or type). Plants have similar structures that contain cellulose, lignin, pectins, and other cell walls called gums that help hold their cells together in larger structures like stems or leaves. Each has varying amounts inside them, depending on the plant.

What Makes Up the Reinforced Part of FRP?

Glass, carbon, and aramid fibers make the “reinforced” part of FRP. Glass fibers are used most often in FRP because they are strong but brittle, so a sharp knife is all you need to cut them to size. Carbon and aramid fibers are also very strong but do not break as easily as glass when bent or twisted around corners, making them better for applications requiring flexibility (like boats).

Applications of Fiber Reinforced Polymer

- Military, aerospace, and automotive industries, among others, have adopted modern composites.

- It is a vital component in the aircraft industry. A Boeing 747’s structure contains approximately 2,000 pounds of composites.

- Because of their lightweight nature, they are used in consumer goods production, such as camera tripods, firearms, musical instruments, and sporting goods.

- FRPs are used in the production of protective equipment with aramid composition.

- FRPs are used as insulation materials in power industries because of their ruggedness and tolerance to withstand pressure.

The last thing you want to worry about when building something is the strength of your materials. A strong material can withstand more load before breaking. Parts of your project made from strong materials are more likely to last longer than weaker materials. The strength of FRPs can be increased by using specific 3D printing techniques by 30-50% and shear strength by 250%. Regarding strength and durability, FRPs have many advantages.

They are 5 to 10 times stronger, less dense, and more malleable than steel. Also, they are more fire resistant, corrosion resistant, and impact resistant. Composites have been around for centuries but have only recently gained popularity in consumer products. They are strong and lightweight, making them suitable for various applications.

When it comes to a dependable and reputable company specializing in fiber reinforced polymer (FRP), DC Byers in Grand Rapids is unrivaled. With years of experience, we are FRP experts in all aspects. Whether you require assistance with repairs, maintenance, or new construction, we can help. We have a team of highly skilled technicians who are always up for a challenge, and we are confident we can handle any project. If you have questions about fiber-reinforced polymers, please contact DC Byers in Grand Rapids at 616-538-7300.